Revolutionizing Piano Restoration with 3D Printing: Replicating a Lost Piano Leg for a Piano in Maine!

Brigham Larson PianosShare

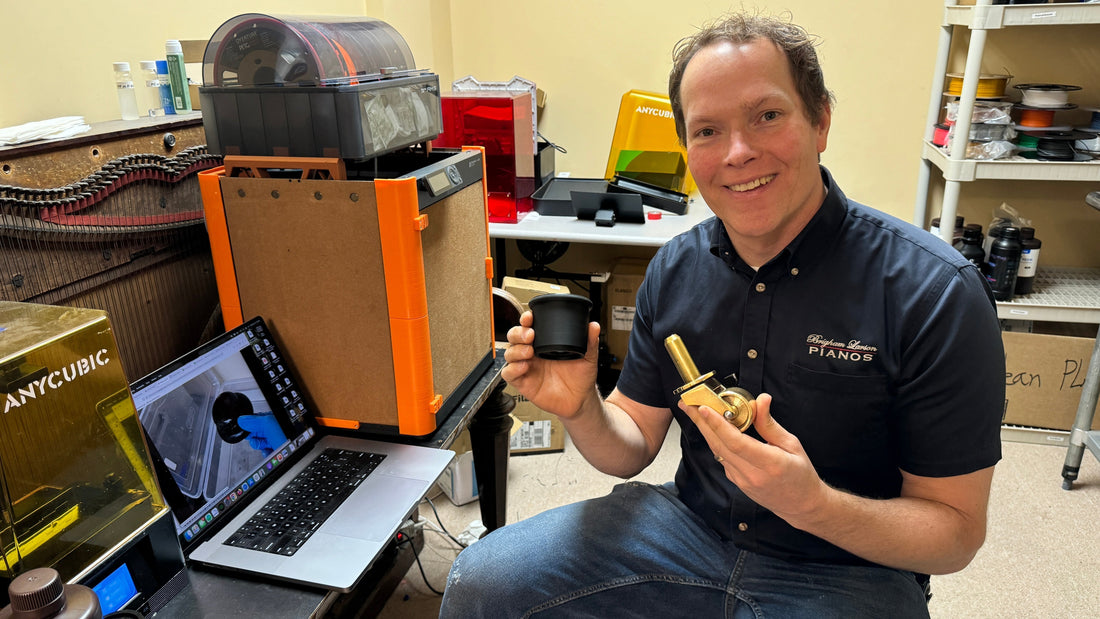

We are now blending timeless piano craftsmanship with innovative 3D piano printing! This is one of the most exciting advancements here in our shop that has opened incredible possibilities for solving complex piano rebuilding challenges.

How 3D Piano Restoration Works

In the shop, I designed a missing leg for a piano in Maine using CAD software, making sure to capture every detail as well as precise intricate dimensions. Using both resin and filament printers, I produced durable parts. After printing, we used our in-house plating shop to plate the components in brass for a seamless, authentic look that matched the piano perfectly!

There are many ways 3D piano restoration can help solve unique challenges when restoring antique and vintage pianos that may seem beyond repair; like designing custom components, or restoring intricate hardware. 3D printing allows us to approach piano restoration with a level of precision and creativity that is truly groundbreaking!

Some components, like rings and hardware, were 3D-printed to match the original design. For structural elements, we used a specialized filament called PETG (Polyethylene Terephthalate Glycol-Modified), known for its strength and durability.

Brass Plating for a Stunning Finish

Instead of painting the brass components, we opted to plate them with real brass using an in-house electroplating process. This method involves painting the non-conductive plastic components with a special metal-infused paint, making them conductive enough for electroplating. The paint contains powdered nickel, which creates the necessary conductivity for the brass plating to adhere effectively, followed by a layer of copper, and finally a brass coating.

After coating with copper, the finish is refined to remove any imperfections revealing a gleaming, polished brass finish that is nearly indistinguishable from the original hardware!